24H全国咨询热线

14

2024

-

12

Aluminum profile industry dynamics: In-depth analysis of the current situation and trends.

1. Market Size and Growth Trends

In recent years, the global aluminum profile market has shown a steady growth trend. With the increasing demand for lightweight and high-strength materials in various fields such as construction, automotive, and industrial manufacturing, aluminum profiles are increasingly applied across industries due to their excellent performance characteristics, such as being lightweight, corrosion-resistant, and recyclable.

In the domestic market, the aluminum profile industry is also developing rapidly. As the world's largest producer and consumer of aluminum, China's aluminum profile output has ranked first in the world for many consecutive years. The booming development of the domestic construction industry, especially the large-scale infrastructure construction, commercial real estate development, and the rise of residential buildings during the urbanization process, has provided a broad market space for aluminum profiles. At the same time, driven by the trend of automotive lightweighting, the application ratio of aluminum profiles in automotive parts manufacturing is gradually increasing, further promoting the expansion of the domestic aluminum profile market.

2. Technological Innovation and Product Upgrading

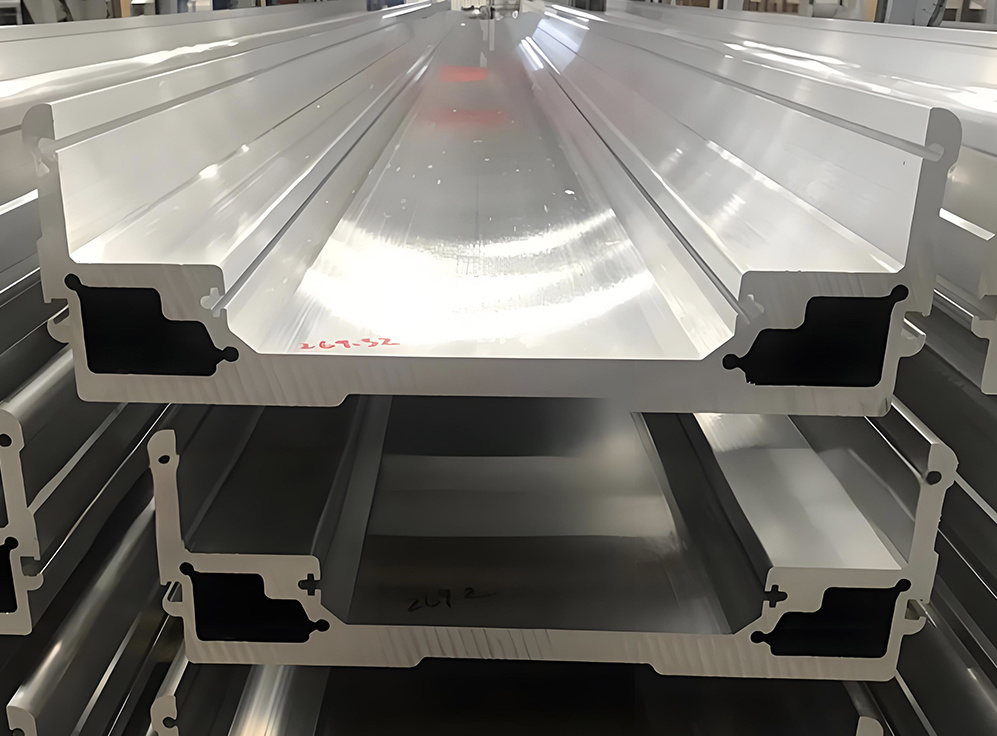

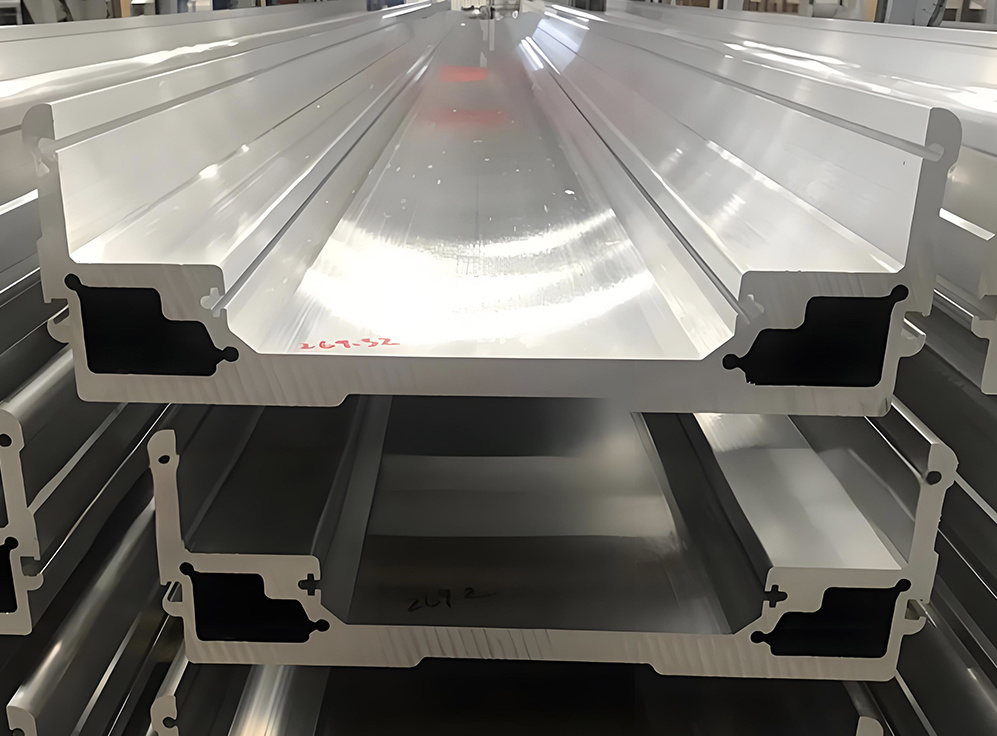

(1) Improvement of Production Processes

Aluminum profile manufacturing enterprises are continuously increasing their R&D investment in production processes to improve production efficiency, reduce costs, and enhance product quality. For example, new extrusion processes can achieve precise forming of aluminum profiles with more complex cross-sectional shapes, improving material utilization; optimization of heat treatment processes can significantly improve the mechanical properties of aluminum profiles, enhancing their strength and hardness. In addition, surface treatment technologies have also made significant progress, with continuous innovations in processes such as anodizing, powder coating, and fluorocarbon paint spraying, which not only give aluminum profiles better decorative and weather-resistant properties but also meet the personalized needs for color and gloss in different application scenarios.

Aluminum profile manufacturing enterprises are continuously increasing their R&D investment in production processes to improve production efficiency, reduce costs, and enhance product quality. For example, new extrusion processes can achieve precise forming of aluminum profiles with more complex cross-sectional shapes, improving material utilization; optimization of heat treatment processes can significantly improve the mechanical properties of aluminum profiles, enhancing their strength and hardness. In addition, surface treatment technologies have also made significant progress, with continuous innovations in processes such as anodizing, powder coating, and fluorocarbon paint spraying, which not only give aluminum profiles better decorative and weather-resistant properties but also meet the personalized needs for color and gloss in different application scenarios.

(2) R&D of High-Performance Products

To meet the demands of the high-end market, enterprises are actively carrying out R&D work on high-performance aluminum profiles. The aerospace field has extremely high requirements for the high strength, low density, and high-temperature resistance of aluminum profiles, prompting relevant enterprises to develop a series of new aluminum alloy materials, such as aluminum-lithium alloy profiles, which significantly reduce weight while ensuring structural strength, providing key support for the performance enhancement of aerospace vehicles.

To meet the demands of the high-end market, enterprises are actively carrying out R&D work on high-performance aluminum profiles. The aerospace field has extremely high requirements for the high strength, low density, and high-temperature resistance of aluminum profiles, prompting relevant enterprises to develop a series of new aluminum alloy materials, such as aluminum-lithium alloy profiles, which significantly reduce weight while ensuring structural strength, providing key support for the performance enhancement of aerospace vehicles.

3. Expansion of Application Fields

(1) Construction Field

The application of aluminum profiles in the construction field is traditional and extensive, covering various aspects such as doors and windows, curtain walls, and building structural frameworks. With the popularization of green building concepts, energy-saving aluminum profiles have become a new favorite in the market. Thermal break aluminum profiles, by adopting thermal insulation break technology, effectively reduce the heat transfer coefficient of doors and windows, improving the thermal insulation performance of buildings, in line with national building energy-saving standards, and expanding market share year by year. At the same time, the rise of prefabricated buildings provides new development opportunities for aluminum profiles, as they serve as important structural materials and connecting components in prefabricated buildings. Their standardized and modular production methods align closely with the construction concepts of prefabricated buildings, significantly shortening construction cycles and improving building quality and safety.

The application of aluminum profiles in the construction field is traditional and extensive, covering various aspects such as doors and windows, curtain walls, and building structural frameworks. With the popularization of green building concepts, energy-saving aluminum profiles have become a new favorite in the market. Thermal break aluminum profiles, by adopting thermal insulation break technology, effectively reduce the heat transfer coefficient of doors and windows, improving the thermal insulation performance of buildings, in line with national building energy-saving standards, and expanding market share year by year. At the same time, the rise of prefabricated buildings provides new development opportunities for aluminum profiles, as they serve as important structural materials and connecting components in prefabricated buildings. Their standardized and modular production methods align closely with the construction concepts of prefabricated buildings, significantly shortening construction cycles and improving building quality and safety.

(2) Automotive Field

The lightweight development trend in the automotive industry is an important driving force for the expansion of aluminum profile applications. The application of aluminum profile components such as aluminum alloy body frames, crash beams, and doors is gradually increasing, which not only helps reduce the weight of vehicles, lower fuel consumption and emissions but also enhances the handling and acceleration performance of cars. In addition, the rapid development of new energy vehicles has opened up broader space for the application of aluminum profiles in the automotive field. Due to the high emphasis on range in new energy vehicles, lightweighting of the vehicle body is particularly important, and the application of aluminum profiles in key components such as battery trays and motor housings is becoming increasingly common. It is expected that the market demand for aluminum profiles in the automotive field will maintain rapid growth in the coming years.

The lightweight development trend in the automotive industry is an important driving force for the expansion of aluminum profile applications. The application of aluminum profile components such as aluminum alloy body frames, crash beams, and doors is gradually increasing, which not only helps reduce the weight of vehicles, lower fuel consumption and emissions but also enhances the handling and acceleration performance of cars. In addition, the rapid development of new energy vehicles has opened up broader space for the application of aluminum profiles in the automotive field. Due to the high emphasis on range in new energy vehicles, lightweighting of the vehicle body is particularly important, and the application of aluminum profiles in key components such as battery trays and motor housings is becoming increasingly common. It is expected that the market demand for aluminum profiles in the automotive field will maintain rapid growth in the coming years.

(3) Industrial Field

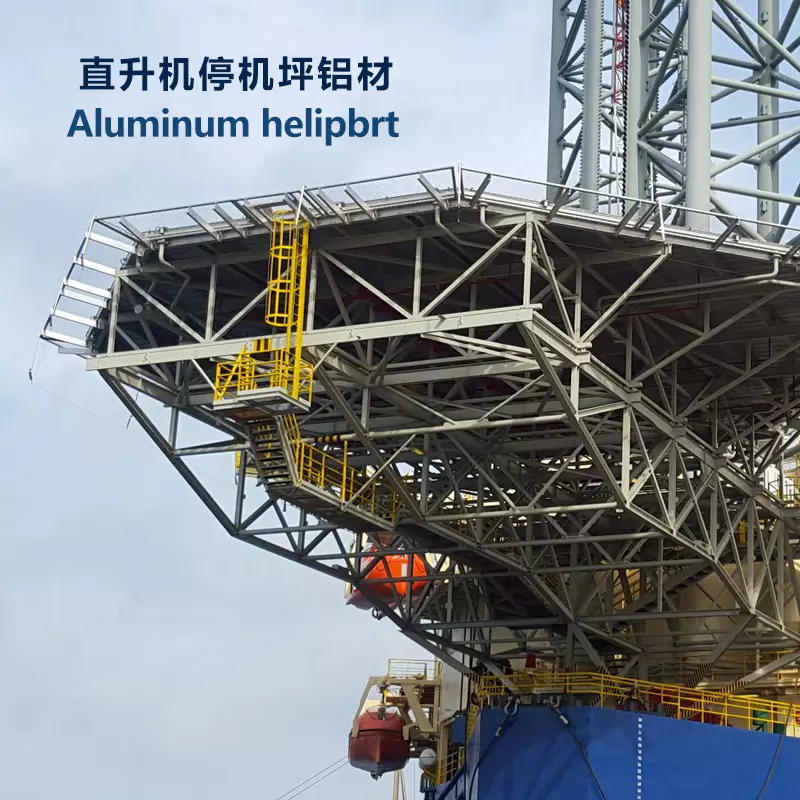

In the industrial manufacturing field, the application range of aluminum profiles is also continuously expanding. Aluminum profiles are widely used in automated production lines, mechanical equipment frames, and warehousing logistics equipment. The ease of processing, assembly, and good conductivity of aluminum profiles enable them to meet the diverse design and manufacturing needs of industrial equipment. For example, in automated production lines, aluminum profiles can serve as components such as guide rails and brackets, and their lightweight and corrosion-resistant characteristics facilitate the installation, debugging, and maintenance of equipment; in warehousing logistics equipment, aluminum profile shelves have advantages such as being lightweight, strong load-bearing capacity, and easy installation, effectively improving warehouse space utilization and goods storage management efficiency.

In the industrial manufacturing field, the application range of aluminum profiles is also continuously expanding. Aluminum profiles are widely used in automated production lines, mechanical equipment frames, and warehousing logistics equipment. The ease of processing, assembly, and good conductivity of aluminum profiles enable them to meet the diverse design and manufacturing needs of industrial equipment. For example, in automated production lines, aluminum profiles can serve as components such as guide rails and brackets, and their lightweight and corrosion-resistant characteristics facilitate the installation, debugging, and maintenance of equipment; in warehousing logistics equipment, aluminum profile shelves have advantages such as being lightweight, strong load-bearing capacity, and easy installation, effectively improving warehouse space utilization and goods storage management efficiency.

In summary, the aluminum profile industry is in a golden period of rapid development under the combined effects of growing market demand, technological innovation, and expansion of application fields. However, industry enterprises also face many challenges such as fierce market competition and sustainable development, requiring continuous strengthening of technological R&D, optimizing product structure, and improving enterprise management levels to adapt to market changes and achieve long-term stable development.

Shandong Chengyi Aluminum Industry Co., Ltd

Shandong Chengyi Aluminum Industry Co., Ltd

Chengbei Industrial District, Gaomi City, Shandong Province, China

Chengbei Industrial District, Gaomi City, Shandong Province, China

Copyright © 2023 Shandong Chengyi Aluminum Industry Co., Ltd