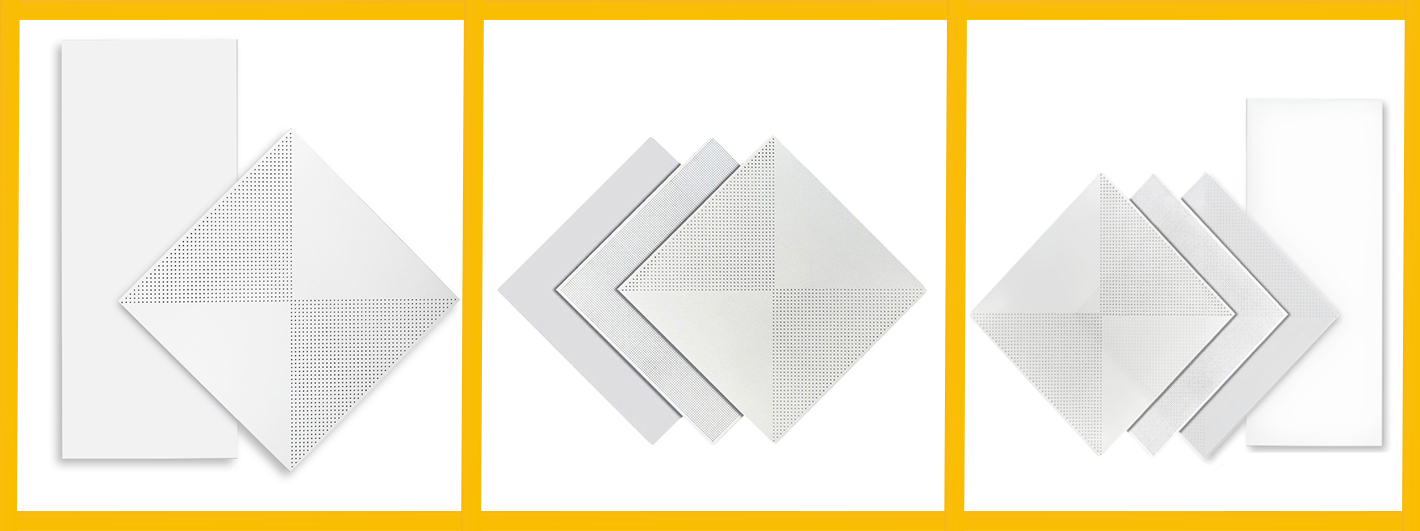

Integrated Ceiling Aluminum Buckle Plate

Keyword:

Category:

Tel:

Phone:

Integrated Ceiling Aluminum Buckle Plate

Aluminum gusset plate

The aluminum gusset plate is obtained by processes such as material cutting, corner cutting, and molding with aluminum alloy sheets as the base. Its surface is processed with various different coatings to form various aluminum gusset plate products. Aluminum gusset plates are mainly divided into two types: home decoration integrated aluminum gusset plates and engineering aluminum gusset plates.

| Product Name | Aluminum gusset plate | Shape | customized |

| Grade | 6000 Series | Technique | Cold Drawn |

| Tolerance | ±1% | Hardness | 8-12HW |

| Place of Origin | Shandong, China | Yield (≥ MPa) | 160 |

| Delivery Time | 8-20 days | Temper | T3 - T8 |

| Brand Name | CHENG YI | Ultimate Strength (≥ MPa) | 205 |

| Application | Construction and other uses | Processing Service | Bending, Decoiling, Welding, Punching, Cutting |

Product features:

Excellent panel coating performance: High-quality aluminum gusset plates generally use high-quality coatings and are coated by imported fully automatic high-speed coating lines. The panel surface is flat and has no color difference.

Very strong composite bond strength: High-quality aluminum gusset plates are made by hot-pressing and compounding selected high-polymer plastics and polymer materials.

Strong temperature adaptability: Aluminum gusset plates can be used under large temperature changes, and their excellent performance is not affected.

Excellent processing performance: Aluminum gusset plates can be processed and formed by cutting, sawing, milling, punching, pressing, folding, and bending with ordinary wood and metal processing tools, and can accurately meet the design and styling requirements.

The panel surface is flat and the edges are distinct: The ceiling system presents a neat, generous, luxurious, elegant, and wide-vision appearance effect. Aluminum gusset plates have the advantages of flame retardancy, anti-corrosion, and moisture resistance. Moreover, they are convenient for installation and disassembly. Each plate can be independently disassembled and assembled, facilitating construction and maintenance.

Aluminum gusset plates have various excellent characteristics and thus are widely used, mainly as follows:

In the field of architectural decoration:

Interior decoration: It can be used for ceilings, featuring fire resistance, moisture resistance, convenient installation, easy cleaning, etc. It has smooth lines, rich colors, and a good appearance, which can add beauty to the interior space.

Exterior decoration: It can be used as a building facade material for balconies, building exterior walls, etc. Its good weather resistance and durability can adapt to various harsh climate environments, and different color and texture effects can be achieved through various surface treatment technologies to enhance the beauty and overall quality of the building.

Commercial space decoration: Commercial places such as shopping malls, hotels, restaurants, cafes, tea restaurants, office buildings, shopping plazas, exhibitions, auto shows, etc. have high requirements for the aesthetics, durability, and maintenance convenience of decoration.

Public building places: Public buildings such as hospitals, airports, stations, schools, kindergartens, banks, clubs, exhibition halls, etc. require decorative materials with properties such as fire resistance, moisture resistance, durability, and easy cleaning.

CY Aluminium (Shandong) Co., Ltd. is headquartered in Tianjin and has branches in Shandong and Jiangsu. Currently, the company mainly produces various high-quality aluminium profiles, aluminium tubes, aluminium square tubes, aluminium bars, aluminium rods, and aluminium for assembly lines, etc.

The main grades include 1060, 1100, 3003, 5052, 5083, 6061, 6063, 6082, 6463, 6005, 6005A, 6060, 7075, etc. We always have stocks available, with a complete variety and prompt delivery.

The company integrates design - mold opening - extrusion - processing - surface treatment for production and has 19 extrusion machines ranging from 600 to 7500 tons. It also possesses modern welding technology and advanced surface treatment technology, such as hard oxidation, oxidation coloring, three-acid bright silver, sandblasting oxidation, acid sand oxidation, alkali sand oxidation, powder coating, wire drawing, etc. In response to the transformation of new and old kinetic energy and oriented by customer demands, we conduct professional design and processing to achieve a better combination of mechanics and aesthetics.

CY Aluminium (Shandong) Co., Ltd. takes "humility, responsibility, innovation and integrity" as its corporate culture, adheres to its duty, integrates knowledge and action, and strives to make aluminium alloy products better.

Next

Next

Related Products