Industrial Aluminum Profiles

Keyword:

Category:

Tel:

Phone:

Industrial Aluminum Profiles

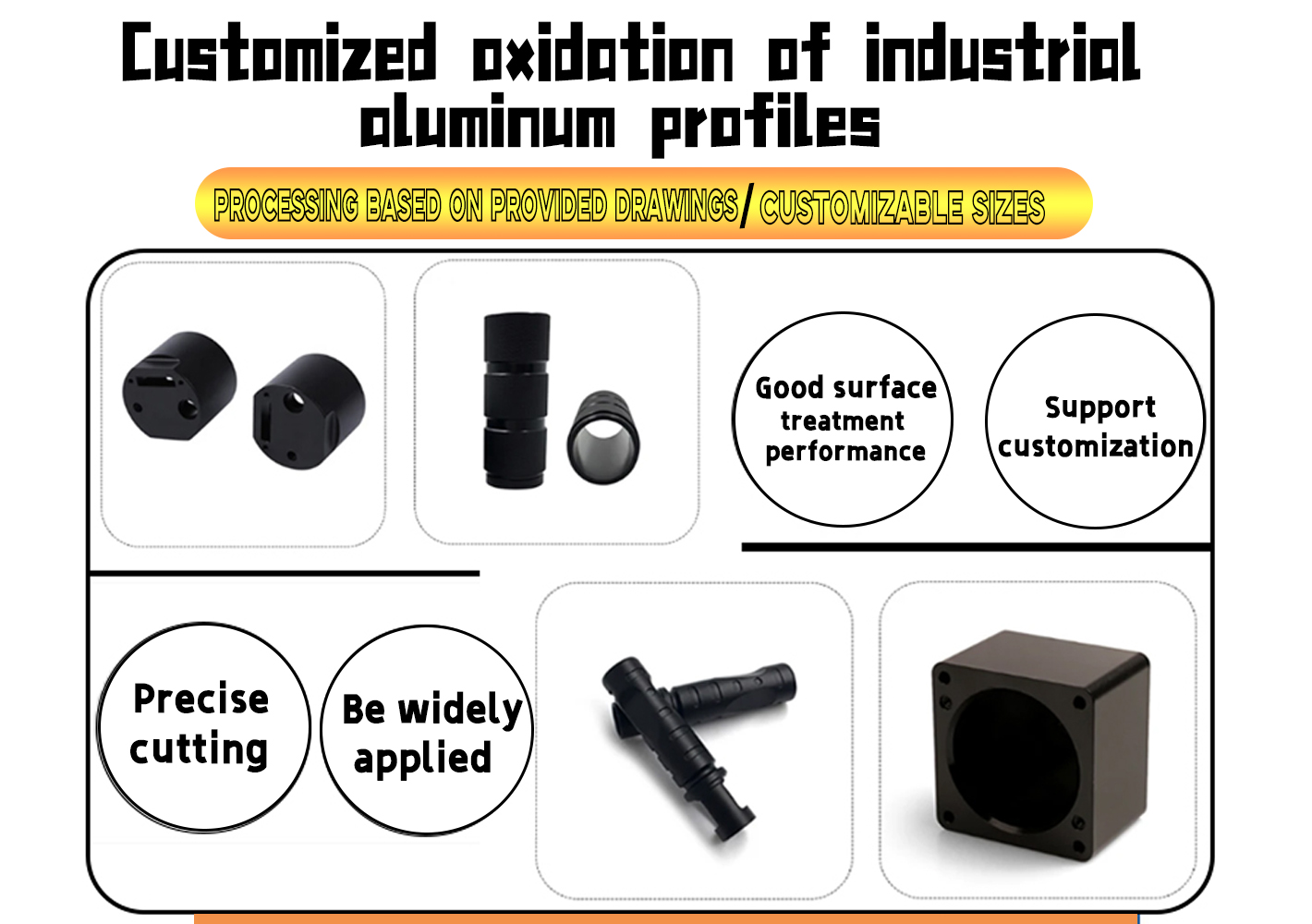

Hard anodizing processing of aluminum is a commonly used surface treatment technology, which can significantly improve the hardness, wear resistance and corrosion resistance of aluminum parts and tubes.

Hard anodizing processing of aluminum is a commonly used surface treatment technology, which can significantly improve the hardness, wear resistance and corrosion resistance of aluminum parts and tubes.

| Product Name | Aluminum profile | Shape | Customized |

| Grade | 6000 Series | Technique | Cold Drawn |

| Tolerance | ±1% | Hardness | 8-12HW |

| Place of Origin | Shandong, China | Yield (≥ MPa) | 160 |

| Delivery Time | 8-20 days | Temper | T3 - T8 |

| Brand Name | CHENG YI | Ultimate Strength (≥ MPa) | 205 |

| Application | Construction and other uses | Processing Service | Bending, Decoiling, Welding, Punching, Cutting |

Features of hard anodizing processing of aluminum:

♦ Increase hardness

After hard anodizing treatment, a hard oxide film is formed on the surface of the aluminum, and its hardness can reach or even exceed that of some metals, greatly enhancing the wear resistance and scratch resistance of aluminum parts and tubes.

This enables them to better withstand friction and wear in various harsh working environments, such as in mechanical manufacturing and the automotive industry.

♦ Enhance corrosion resistance

The hard oxide film has good chemical stability and can effectively resist the erosion of corrosive media such as acids, alkalis, and salts.

This is crucial for aluminum products used in humid and corrosive environments and can extend their service life.

♦ Beautiful and durable

Hard anodizing treatment can make the aluminum surface present various colors, such as black, gray, gold, etc., increasing the aesthetic appeal of the product.

At the same time, the oxide film has strong adhesion and is not easy to fall off, making the aluminum parts and tubes more durable.

Advantages of CNC Machining in Aluminum Processing

♦ High-precision machining

CNC (Computer Numerical Control) machining technology can achieve high-precision cutting and processing, and can meet the processing requirements of various complex shapes and sizes of aluminum parts and tubes.

Through programming control, the processing path and cutting parameters can be precisely controlled to ensure the dimensional accuracy and surface quality of the product.

♦ High-efficiency production

CNC processing equipment has a high degree of automation and can perform continuous processing, greatly improving production efficiency.

Compared with traditional manual processing or ordinary machine tool processing, CNC processing can complete more processing tasks in a shorter time.

♦ Strong flexibility

CNC processing can be quickly adjusted and programmed according to different design requirements to adapt to the processing of various types of aluminum parts and tubes.

Whether it is single-piece production or batch production, it can be easily handled.

CY Aluminium (Shandong) Co., Ltd. is headquartered in Tianjin and has branches in Shandong and Jiangsu. Currently, the company mainly produces various high-quality aluminium profiles, aluminium tubes, aluminium square tubes, aluminium bars, aluminium rods, and aluminium for assembly lines, etc.

The main grades include 1060, 1100, 3003, 5052, 5083, 6061, 6063, 6082, 6463, 6005, 6005A, 6060, 7075, etc. We always have stocks available, with a complete variety and prompt delivery.

The company integrates design - mold opening - extrusion - processing - surface treatment for production and has 19 extrusion machines ranging from 600 to 7500 tons. It also possesses modern welding technology and advanced surface treatment technology, such as hard oxidation, oxidation coloring, three-acid bright silver, sandblasting oxidation, acid sand oxidation, alkali sand oxidation, powder coating, wire drawing, etc. In response to the transformation of new and old kinetic energy and oriented by customer demands, we conduct professional design and processing to achieve a better combination of mechanics and aesthetics.

CY Aluminium (Shandong) Co., Ltd. takes "humility, responsibility, innovation and integrity" as its corporate culture, adheres to its duty, integrates knowledge and action, and strives to make aluminium alloy products better.

Related Products