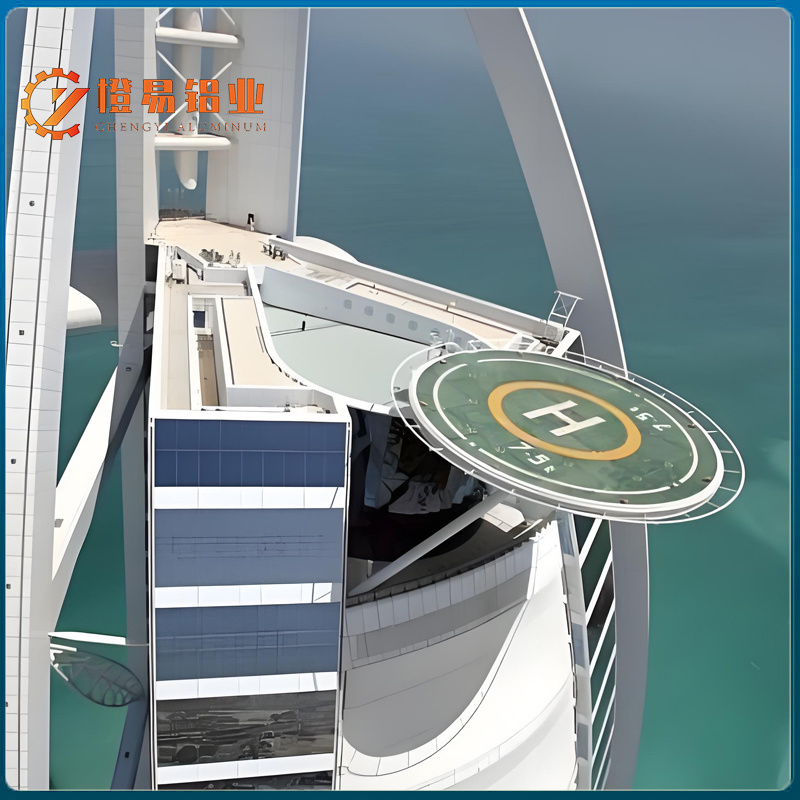

Helicopter landing pad

Keywords:

Category:

Hotline:

Tel:

Helicopter landing pad

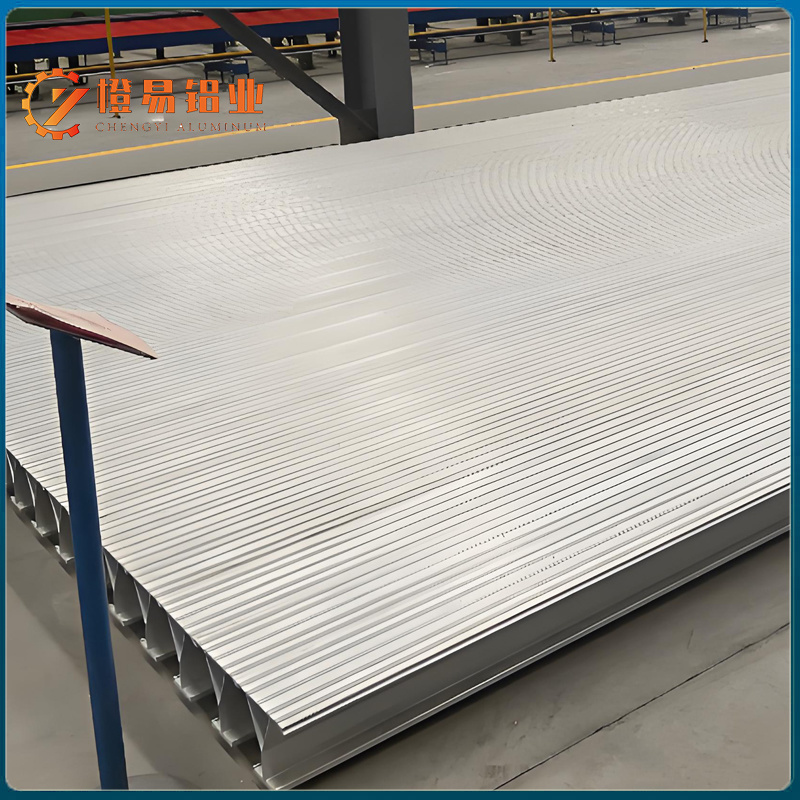

Aluminum alloy profile square tubes are a type of square tubular profiles with aluminum alloy as the main material.

| Product Name | Aluminium alloy level | Shape | Customize |

| Grade | 6000 Series | Standard | AiSi, ASTM, BS, DIN, GB, JIS |

| Tolerance | ±1% | Length | according to customer |

| Place of Origin | Shandong, China | Color | Original color of aluminium |

| Delivery Time | 8-20 days | Packing | Standard Seaworthy Standards |

| Brand Name | CHENG YI | Application | Building, Roofing |

| Application | Construction and other uses | Processing Service | Welding, Punching, Cutting, Bending, Decoiling |

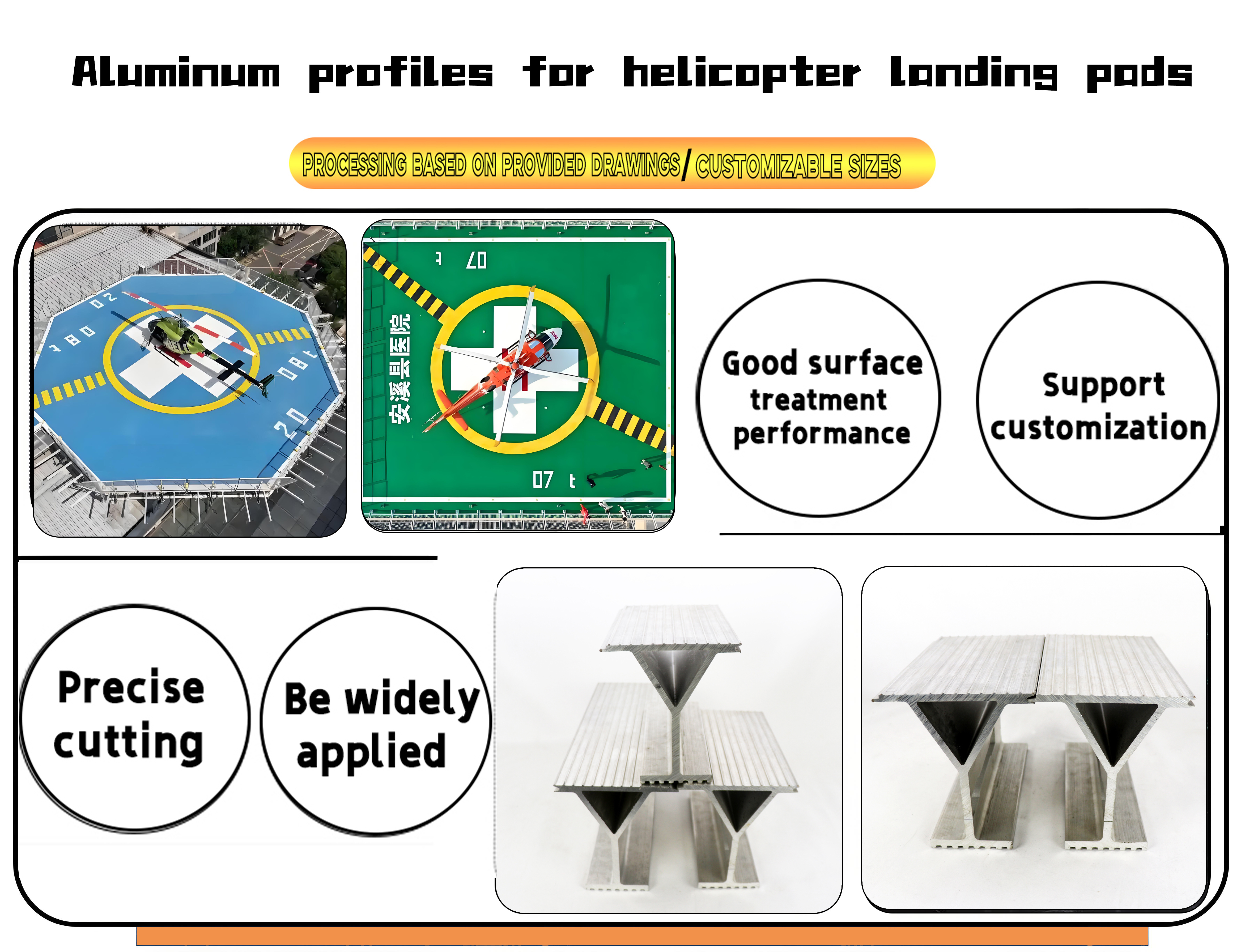

The advantages and applications of aluminium materials for helicopter landing pads are as follows:

Light weight: The density of aluminium is low, much lower than many common metals, which can significantly reduce the weight of the landing pad and facilitate transportation and installation. For example, the marine aluminium alloy landing pad with a length and width of over 22 meters manufactured by Taiyi Aviation weighs only 20 tons.

Corrosion resistance: Aluminium easily forms a dense aluminium oxide film in the air, preventing further oxidation inside, making it highly corrosion-resistant. It can resist the erosion of outdoor moist air, rainwater, seawater, etc., and has a long service life.

High strength: By adding alloying elements and optimizing the processing technology, aluminium alloys have high strength, comparable to high-strength steel, and can meet the bearing requirements during helicopter takeoff and landing.

Easy processing: Aluminium materials have good plasticity and processability and can be made into components of various shapes and sizes through various processing methods. The manufacturing accuracy is high, meeting the structural requirements of different parts of the landing pad.

Recyclability: Aluminium has high recycling and reuse value, low recycling energy consumption, and little performance loss. Scrap aluminium materials from the landing pad can be recycled, which is conducive to saving resources and protecting the environment.

CY Aluminium (Shandong) Co., Ltd. is headquartered in Tianjin and has branches in Shandong and Jiangsu. Currently, the company mainly produces various high-quality aluminium profiles, aluminium tubes, aluminium square tubes, aluminium bars, aluminium rods, and aluminium for assembly lines, etc.

CY Aluminium (Shandong) Co., Ltd. is headquartered in Tianjin and has branches in Shandong and Jiangsu. Currently, the company mainly produces various high-quality aluminium profiles, aluminium tubes, aluminium square tubes, aluminium bars, aluminium rods, and aluminium for assembly lines, etc.

The main grades include 1060, 1100, 3003, 5052, 5083, 6061, 6063, 6082, 6463, 6005, 6005A, 6060, 7075, etc. We always have stocks available, with a complete variety and prompt delivery.

The company integrates design - mold opening - extrusion - processing - surface treatment for production and has 19 extrusion machines ranging from 600 to 7500 tons. It also possesses modern welding technology and advanced surface treatment technology, such as hard oxidation, oxidation coloring, three-acid bright silver, sandblasting oxidation, acid sand oxidation, alkali sand oxidation, powder coating, wire drawing, etc. In response to the transformation of new and old kinetic energy and oriented by customer demands, we conduct professional design and processing to achieve a better combination of mechanics and aesthetics.

CY Aluminium (Shandong) Co., Ltd. takes "humility, responsibility, innovation and integrity" as its corporate culture, adheres to its duty, integrates knowledge and action, and strives to make aluminium alloy products better.

Related Products