Extruded and Custom - Molded Aluminum Profiles for Mechanical Parts

Keywords:

Category:

Hotline:

Tel:

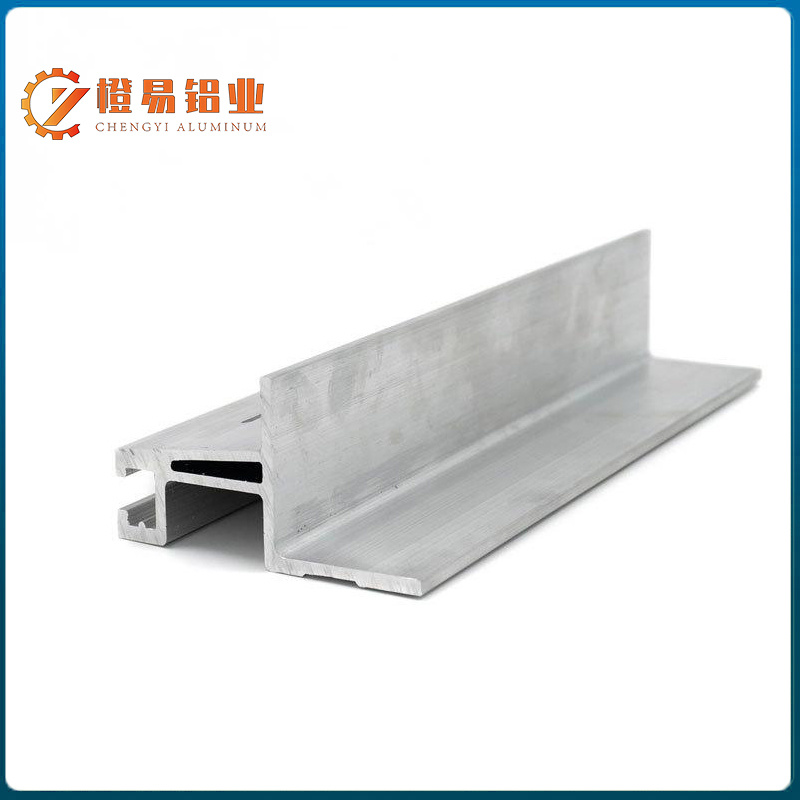

Extruded and Custom - Molded Aluminum Profiles for Mechanical Parts

Extruded and Custom - Molded Aluminum Profiles for Mechanical Parts

Features of Extruded and Custom - Molded Aluminum Profiles for Mechanical Parts :

High Customization

With the extrusion and custom - mold process, aluminum profiles with complex shapes can be fabricated according to the unique designs of mechanical parts. Whether it's a special cross - sectional shape or a structure with specific holes and grooves, they can be accurately created to fully meet the diverse design demands of the machinery industry.

Excellent Mechanical Properties

Aluminum alloy itself has a high strength - to - weight ratio. After extrusion forming and appropriate heat treatment, the customized aluminum - profile mechanical parts possess excellent strength, hardness and toughness. While ensuring the structural stability of the parts, compared with traditional steel parts, it can effectively reduce the weight of the equipment and energy consumption.

Remarkable Processing Cost Advantage

Extrusion and custom - mold customization has a prominent cost advantage in mass production. Once the mold is made, in subsequent production, only the aluminum alloy billet needs to be quickly processed into the required profile through the extrusion equipment. The production efficiency is high and the unit cost is low. Moreover, the good cutting - processing performance of aluminum profiles also reduces the difficulty and cost of subsequent machining.

Strong Corrosion Resistance

A dense oxide film is easily formed on the surface of aluminum alloy. This oxide film can effectively block external oxygen, moisture and corrosive media, enabling the customized aluminum profiles for mechanical parts to have strong corrosion resistance in various environments. It reduces the damage and maintenance costs of parts caused by corrosion and extends the service life of parts.

CY Aluminium (Shandong) Co., Ltd. is headquartered in Tianjin and has branches in Shandong and Jiangsu. Currently, the company mainly produces various high-quality aluminium profiles, aluminium tubes, aluminium square tubes, aluminium bars, aluminium rods, and aluminium for assembly lines, etc.

CY Aluminium (Shandong) Co., Ltd. is headquartered in Tianjin and has branches in Shandong and Jiangsu. Currently, the company mainly produces various high-quality aluminium profiles, aluminium tubes, aluminium square tubes, aluminium bars, aluminium rods, and aluminium for assembly lines, etc.

The main grades include 1060, 1100, 3003, 5052, 5083, 6061, 6063, 6082, 6463, 6005, 6005A, 6060, 7075, etc. We always have stocks available, with a complete variety and prompt delivery.

The company integrates design - mold opening - extrusion - processing - surface treatment for production and has 19 extrusion machines ranging from 600 to 7500 tons. It also possesses modern welding technology and advanced surface treatment technology, such as hard oxidation, oxidation coloring, three-acid bright silver, sandblasting oxidation, acid sand oxidation, alkali sand oxidation, powder coating, wire drawing, etc. In response to the transformation of new and old kinetic energy and oriented by customer demands, we conduct professional design and processing to achieve a better combination of mechanics and aesthetics.

CY Aluminium (Shandong) Co., Ltd. takes "humility, responsibility, innovation and integrity" as its corporate culture, adheres to its duty, integrates knowledge and action, and strives to make aluminium alloy products better.

Related Products