Aluminum Alloy Housings

Keywords:

Category:

Hotline:

Tel:

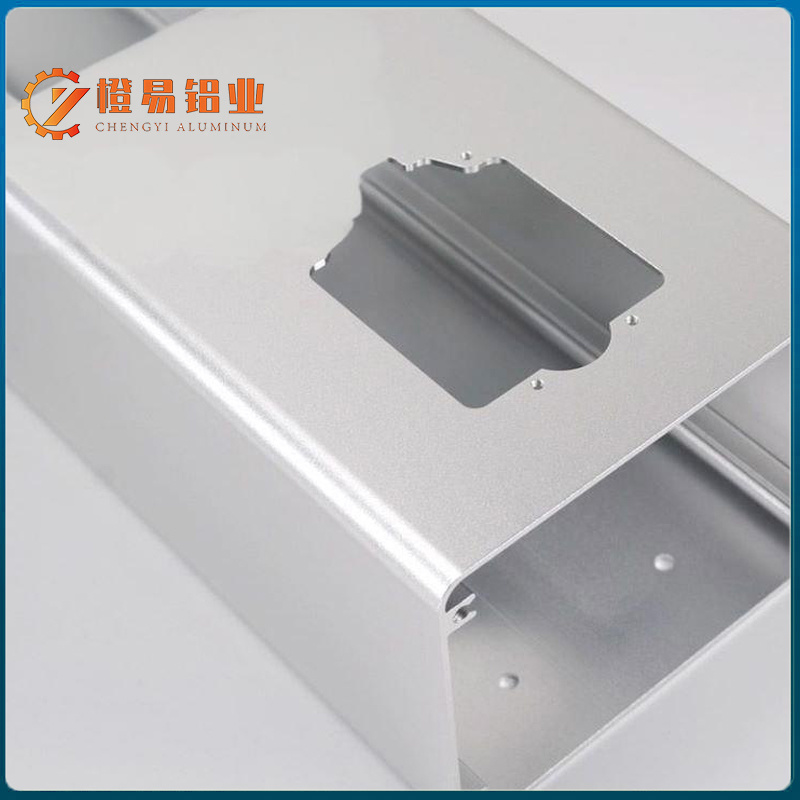

Aluminum Alloy Housings

Features and Applications of Aluminum Profiles for Civil and Commercial New Energy Charging Pole Housings

Features and Applications of Aluminum Profiles for Civil and Commercial New Energy Charging Pole Housings:

Features

Excellent Electrical Conductivity: Aluminum itself has good electrical conductivity. For charging poles, it has certain advantages in ensuring power transmission. It can assist the internal circuit system to achieve more efficient power transmission and reduce energy loss caused by resistance.

Good Heat Dissipation: Heat is generated during the charging process of new energy vehicles. The high thermal conductivity of aluminum profiles can quickly conduct the internal heat to the outside and dissipate heat through the contact between the housing and the air, maintaining the internal electronic components of the charging pole to work at an appropriate temperature, improving the stability and service life of the charging pole.

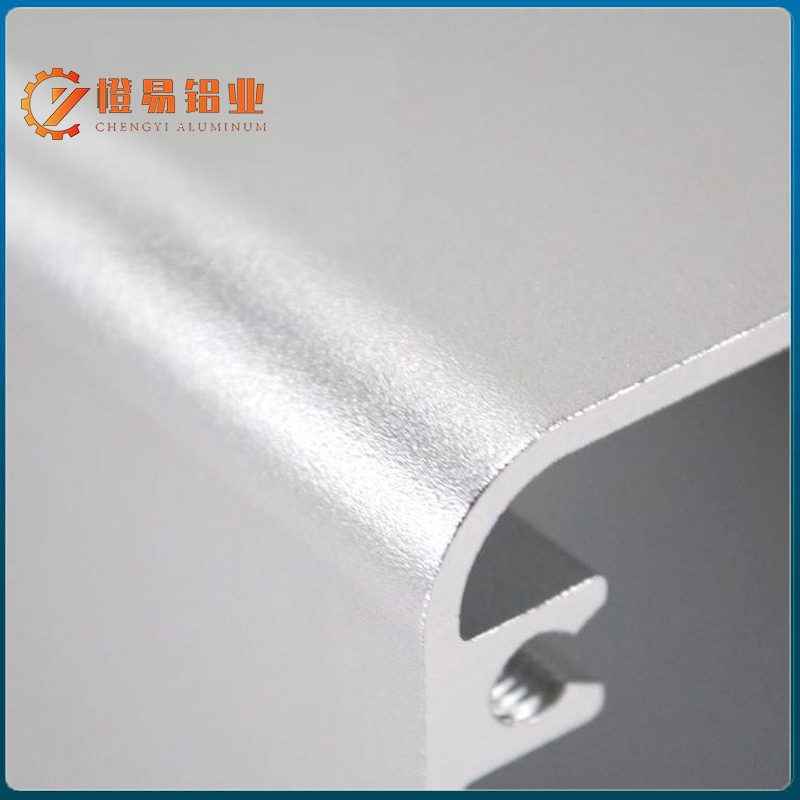

Lightweight and High Strength: Compared with traditional steel, the density of aluminum profiles is about one-third that of steel, which is much lighter in weight and convenient for transportation and installation. At the same time, after alloying and processing, aluminum profiles have high strength and can withstand certain external impacts, meeting the requirements for the firmness of charging pole housings in civil and commercial environments.

Strong Corrosion Resistance: A dense aluminum oxide protective film is easily formed on the surface of aluminum. This oxide film can effectively prevent further oxidation and corrosion of aluminum. Whether in a humid outdoor environment or a commercial place where it may come into contact with corrosive substances, the aluminum profile housing can maintain good physical properties, is not easy to rust or corrode during long-term use, and reduces maintenance costs.

Good Processability: Aluminum profiles can be easily made into various complex shapes and structures through various processing methods such as extrusion, stretching, and bending, meeting the housing requirements of charging poles with different design styles. For example, housings with streamlined appearances and unique shapes can be manufactured to enhance the aesthetics and recognition of charging poles in civil and commercial scenarios.

Recyclability: Aluminum is a recyclable metal material. After the charging pole housing reaches the end of its service life, the aluminum profiles can be recycled and reprocessed and put back into production, which conforms to the current environmental protection concept and reduces resource waste and environmental pressure.

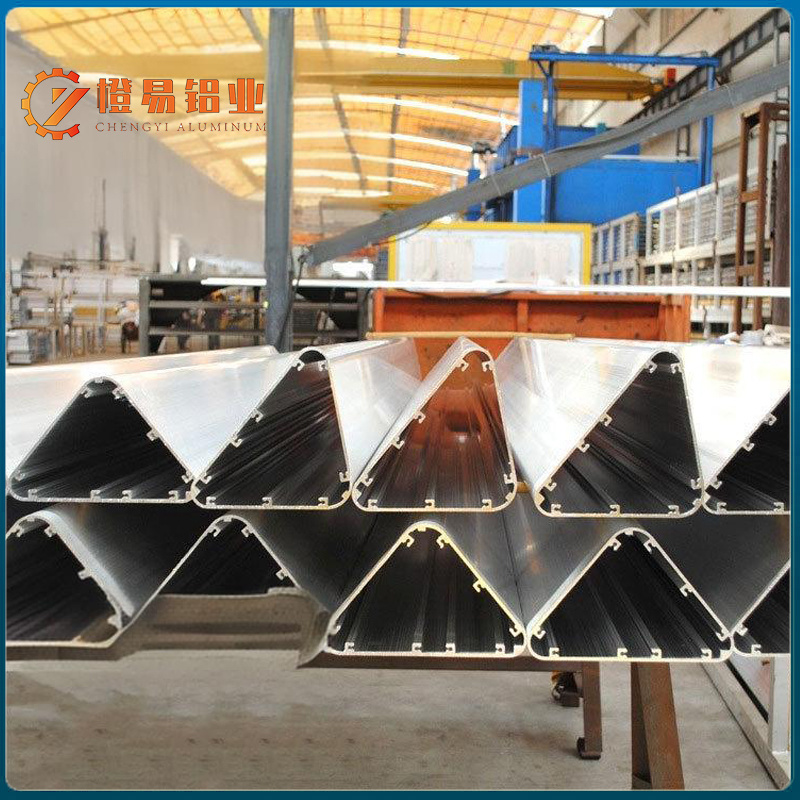

CY Aluminium (Shandong) Co., Ltd. is headquartered in Tianjin and has branches in Shandong and Jiangsu. Currently, the company mainly produces various high-quality aluminium profiles, aluminium tubes, aluminium square tubes, aluminium bars, aluminium rods, and aluminium for assembly lines, etc.

CY Aluminium (Shandong) Co., Ltd. is headquartered in Tianjin and has branches in Shandong and Jiangsu. Currently, the company mainly produces various high-quality aluminium profiles, aluminium tubes, aluminium square tubes, aluminium bars, aluminium rods, and aluminium for assembly lines, etc.

The main grades include 1060, 1100, 3003, 5052, 5083, 6061, 6063, 6082, 6463, 6005, 6005A, 6060, 7075, etc. We always have stocks available, with a complete variety and prompt delivery.

The company integrates design - mold opening - extrusion - processing - surface treatment for production and has 19 extrusion machines ranging from 600 to 7500 tons. It also possesses modern welding technology and advanced surface treatment technology, such as hard oxidation, oxidation coloring, three-acid bright silver, sandblasting oxidation, acid sand oxidation, alkali sand oxidation, powder coating, wire drawing, etc. In response to the transformation of new and old kinetic energy and oriented by customer demands, we conduct professional design and processing to achieve a better combination of mechanics and aesthetics.

CY Aluminium (Shandong) Co., Ltd. takes "humility, responsibility, innovation and integrity" as its corporate culture, adheres to its duty, integrates knowledge and action, and strives to make aluminium alloy products better.

Related Products