26

2024

-

12

Color anodized aluminum tube industry dynamics: market opportunities and challenges coexist.

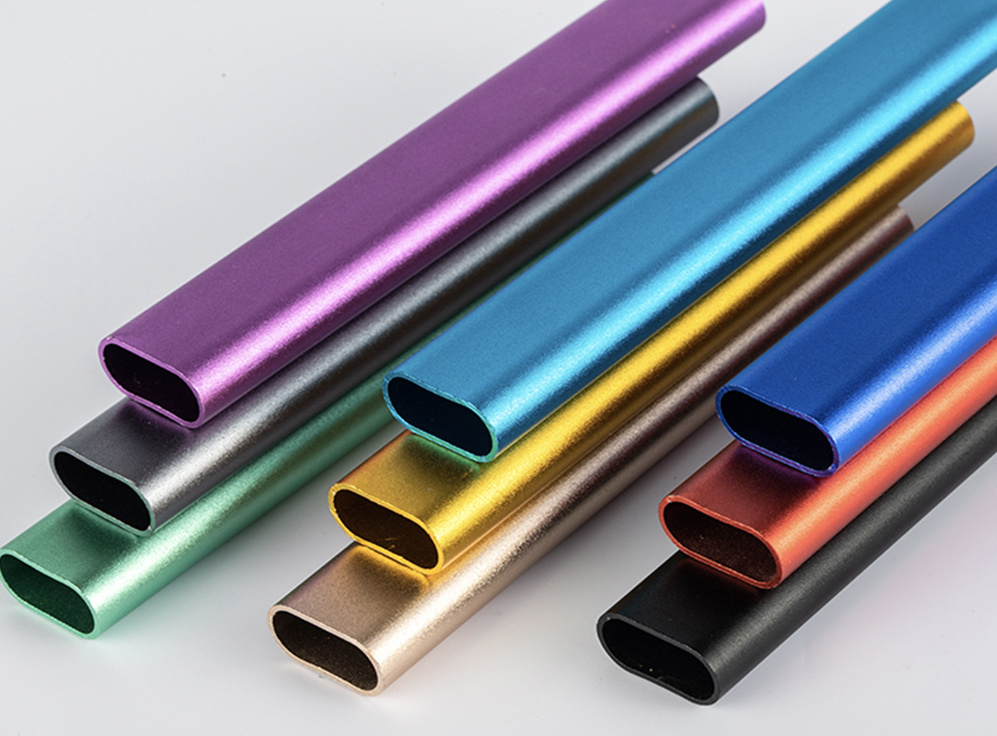

In today's rapidly developing field of materials science, colored aluminum tubes are gradually emerging as a new type of material that combines aesthetics and performance, attracting widespread attention. Their unique color effects and excellent physical properties show broad application prospects in various fields such as architectural decoration, automotive manufacturing, and aerospace. However, with the continuous growth of market demand, the colored aluminum tube industry also faces unprecedented opportunities and challenges.

1. Changes in Market Demand

- The Booming Development of the Architectural Decoration Field

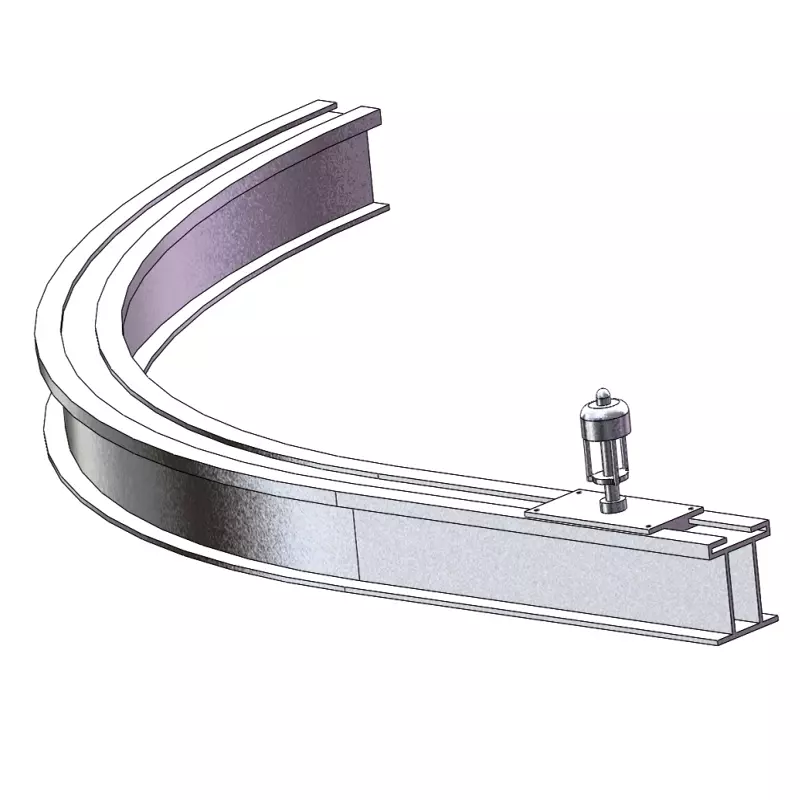

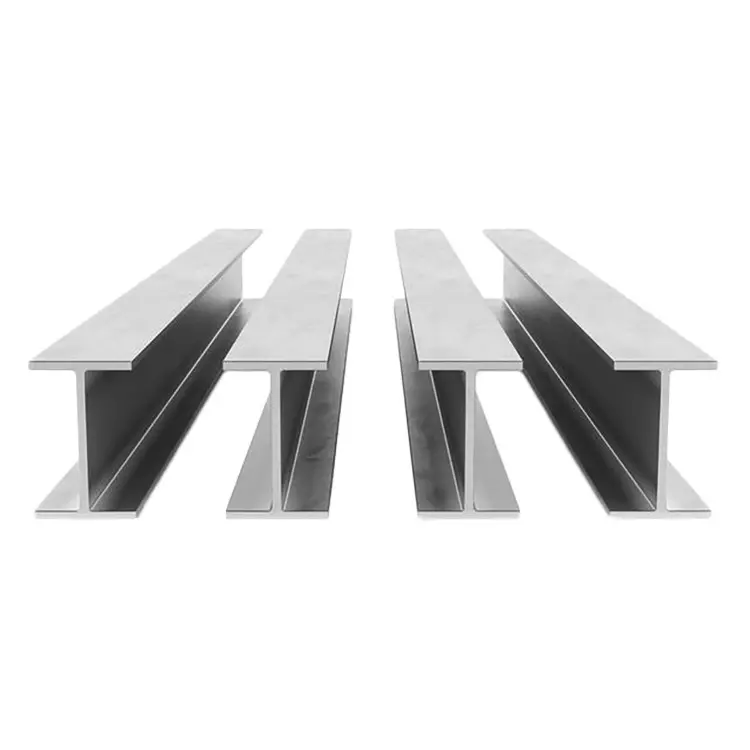

With the increasing diversification of modern architectural styles and the continuous improvement of people's aesthetic requirements for building appearances, the application of colored aluminum tubes in decorative parts such as building curtain walls, railings, and handrails is becoming more widespread. Especially in high-end commercial buildings, office buildings, and luxury residential projects, colored aluminum tubes can add unique visual effects and a modern atmosphere to buildings with their rich color choices, good weather resistance, and metallic texture, making them one of the favored decorative materials for architects and designers. This has led to a stable growth trend in the demand for colored aluminum tubes in the construction industry, along with higher requirements for product specifications, color customization, and surface treatment processes. - Emerging Demand in the Industrial Manufacturing Field

In the industrial manufacturing field, colored aluminum tubes are also gradually gaining prominence. For example, in electronic device manufacturing, their excellent thermal conductivity and insulation properties combined with a colorful appearance can meet the personalized design needs of product appearances and are used in heat dissipation components and decorative parts of electronic products. At the same time, in high-end manufacturing industries such as automotive manufacturing and aerospace, colored aluminum tubes are being explored for use in specific components due to their lightweight, high strength, and corrosion resistance characteristics. Although the current application range is relatively limited, the potential market demand is enormous and is expected to achieve rapid growth with further technological breakthroughs.

2. Technological Innovation and R&D Progress

- Continuous Optimization of Production Processes

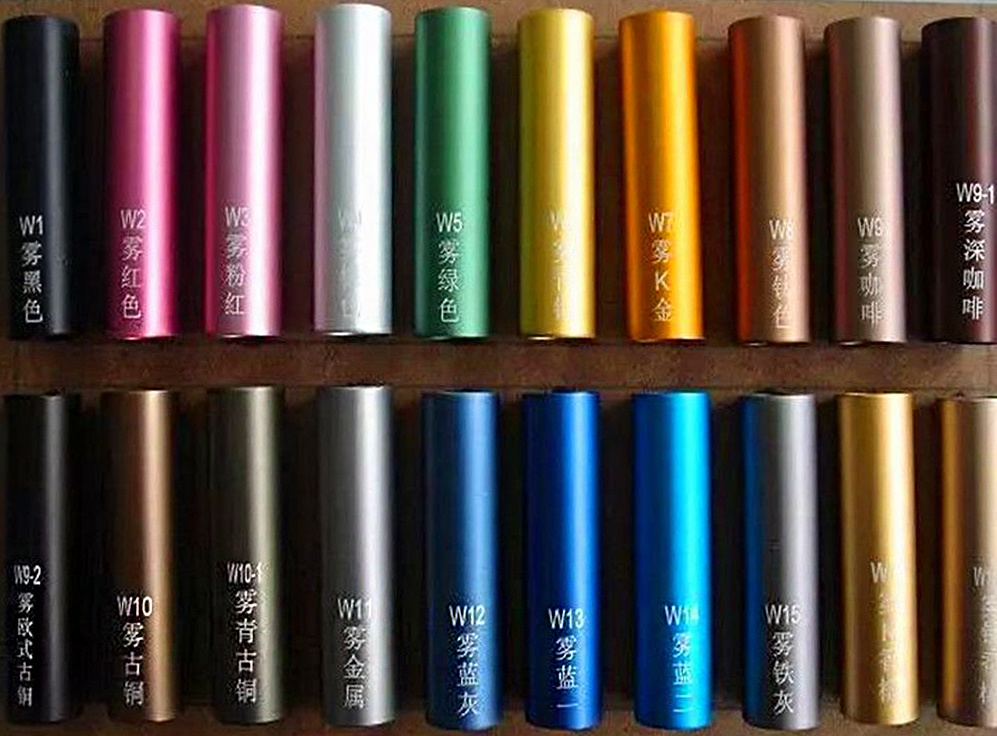

To improve the quality and production efficiency of colored aluminum tubes while reducing production costs, companies are continuously increasing R&D investment in production processes. On one hand, improvements are made to the anodizing process by precisely controlling various parameters during the oxidation process such as electrolyte concentration, temperature, current density, and oxidation time to achieve precise control over oxide film thickness, hardness, and porosity. This enhances the wear resistance, corrosion resistance, and color adhesion of the tubes. On the other hand, significant progress has been made in dyeing technology by using new organic dyes and inorganic pigments combined with advanced dyeing processes such as micro-arc oxidation dyeing and laser-induced dyeing. This not only broadens the color range but also produces more vibrant, durable, and evenly colored aluminum tubes while meeting different customer needs for special color effects (such as fluorescence or color change). - Improvement and Expansion of Material Properties

In addition to traditional performance advantages, researchers are also committed to developing colored aluminum tubes with special properties to meet high-end application needs in specific fields. For example, by adding trace elements or using special heat treatment processes in the aluminum oxide matrix to endow the tubes with better high-temperature resistance, fatigue resistance, and electromagnetic shielding properties. At the same time, for potential applications in biomedicine, colored aluminum tubes with biocompatibility and antibacterial properties have been developed to lay a foundation for their use in medical devices and implants. Although these special performance colored aluminum tubes have not yet achieved large-scale commercial applications, they represent an important direction for future technological development and are expected to open new market growth points for the industry.

3. Environmental Protection and Sustainable Development Trends

- Promotion of Green Production Processes

With the increasing global awareness of environmental protection and increasingly stringent environmental regulations, the colored aluminum tube industry is also facing greater environmental pressure. Against this backdrop, companies are intensifying their R&D efforts in green production processes. For example, adopting chromium-free passivation processes instead of traditional chromium-containing passivation processes reduces emissions of heavy metal pollutants; optimizing energy management during production processes by using energy-saving equipment and technologies reduces energy consumption; at the same time strengthening treatment and recycling of wastewater, waste gas, and waste residue achieves cleaner production processes and efficient resource utilization effectively reducing environmental risks for companies while enhancing their sustainable development capabilities. - Sustainable Design and Recycling of Products

In addition to green production processes, sustainable design of products and recycling have also become important trends in industry development. During product design stages, companies pay more attention to material selection and optimization of product structures to enhance product lifespan and recyclability. For example, using biodegradable packaging materials reduces packaging waste's impact on the environment; at the same time considering structures that facilitate disassembly and recycling during product design allows effective recycling and reuse of colored aluminum tubes after their lifespan ends. Currently, although recycling technology for colored aluminum tubes is still under development stages it has already attracted significant attention from industry enterprises and related research institutions; some preliminary recycling plans and technologies have begun pilot applications which are expected to gradually improve and achieve large-scale promotion providing strong support for sustainable development in the industry.