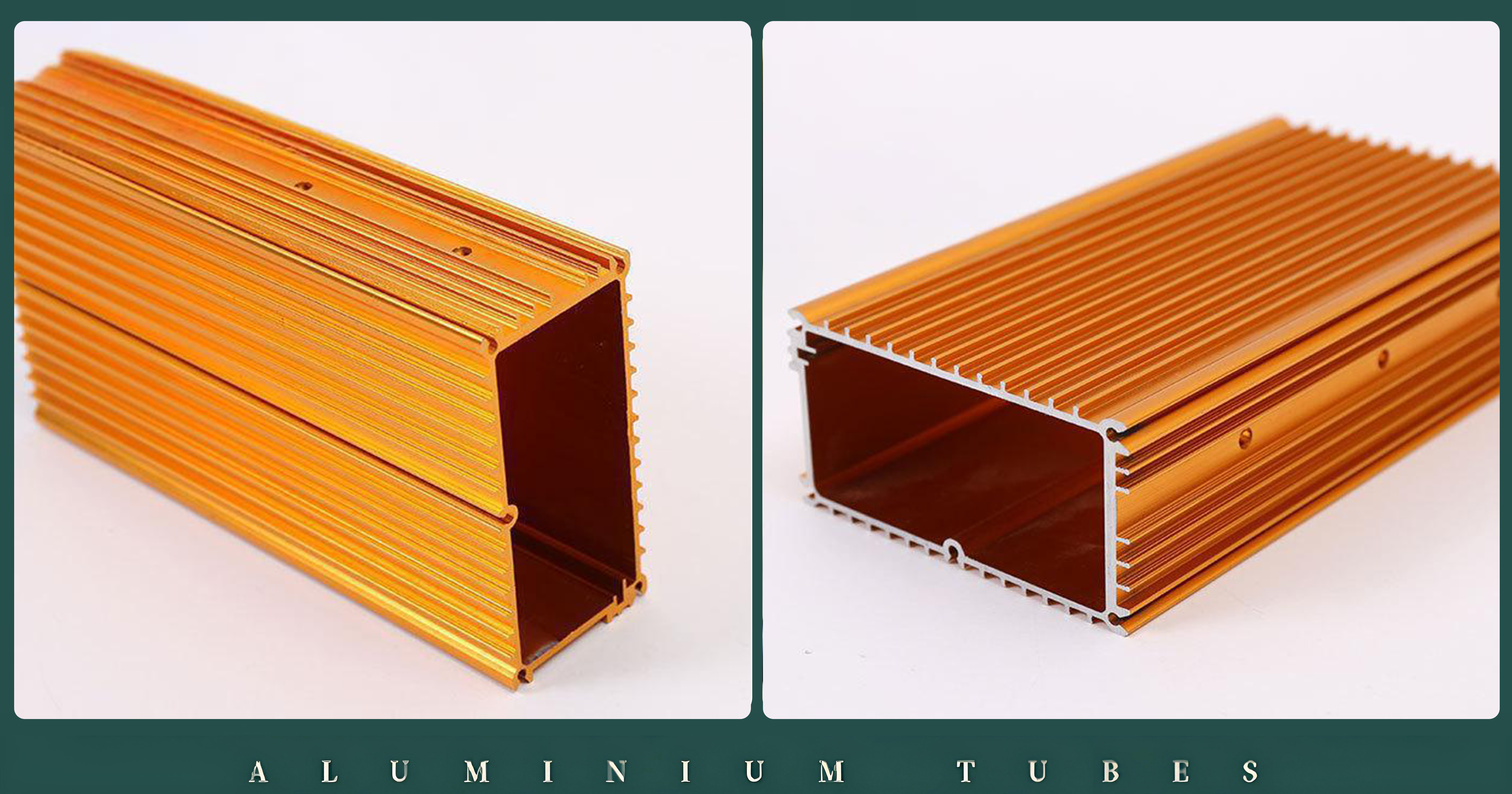

Extruded aluminum profile for heat sink casing

Keyword:

Category:

Tel:

Phone:

Extruded aluminum profile for heat sink casing

Excellent Thermal Conductivity: The thermal conductivity of aluminum alloy is generally between 120-240W/(m・K), which is much higher than that of plastics and stainless steel. It can quickly transfer heat to the surface of the heat sink and dissipate it.

Lightweight Design: Aluminum alloy has a low density and is lightweight. For the same specifications, its weight is only 1/3 that of a steel heat sink, making it easy to install and transport.

Strong Plasticity: Aluminum alloy has good plasticity and machinability. It can be processed into complex shapes and structures through extrusion, stamping, welding, and other processes to meet the heat dissipation needs of different scenarios.

Good Corrosion Resistance: A dense oxide film can be formed on the surface of the aluminum alloy, which can resist erosion from moisture, acidic substances, etc., allowing for long-term use in harsh environments.

Aesthetic Appearance: After surface treatment (such as anodizing, spraying, etc.), aluminum alloy heat sinks can achieve a variety of colors and textures, and have high decorative properties.

Recyclable: Aluminum alloy is a recyclable material that meets environmental requirements. Waste heat sinks can be reprocessed and reused.

Relatively Low Cost: The manufacturing process of aluminum alloy heat sinks is relatively simple, and the production cost is low. The price of aluminum is also much lower than that of copper, resulting in high cost-effectiveness.

Applications of Aluminum Alloy Heat Sinks

Electronics Field: Widely used in computer CPU heat sinks, graphics card heat sinks, etc., it can quickly transfer heat from heat-generating components. The complex fin structure increases the heat dissipation area, further improving heat dissipation efficiency.

Automotive Industry: Used in automotive engine radiators, aluminum alloy radiators can withstand the high temperatures and pressures during engine operation, effectively dissipating heat and improving combustion efficiency and performance.

Construction Field: Used as heating radiators, aluminum alloy radiators have large and fast heat dissipation, and have an aesthetically pleasing appearance, reducing heat loss and meeting the requirements of building energy saving and aesthetics.

Other Industrial Fields: Such as wind power generation, engineering machinery, air compressors, railway locomotives, etc., aluminum alloy heat sinks can be used for the heat dissipation needs of various equipment.

Chengyi Aluminum Industry (Shandong) Co., Ltd. is headquartered in Tianjin and has branch offices in Shandong and Jiangsu. The company currently mainly produces various high-quality aluminum profiles, aluminum tubes, aluminum square tubes, aluminum rods, aluminum strips, and conveyor line aluminum materials, etc. The main grades include 1060, 1100, 3003, 5052, 5083, 6061, 6063, 6082, 6463, 6005, 6005A, 6060, 7075, etc. We have a large stock of these materials, a wide variety of products, and fast delivery.

The company has integrated production from design to mold making, extrusion, processing, and surface treatment, with 19 extrusion machines ranging from 600 to 7500 tons. We also have modern welding technology and advanced surface treatment technology, including hard anodizing, color anodizing, three-acid bright silver, sandblasting anodizing, acid sandblasting anodizing, alkali sandblasting anodizing, powder coating, and wire drawing, etc. In response to the transformation of old and new kinetic energy, we are customer-oriented, professionally designed and processed, achieving a better combination of mechanics and aesthetics.

Chengyi people adhere to the corporate culture of "humility, responsibility, innovation, and integrity," upholding our principles and striving to make aluminum alloy products even better!

Related Products