Custom-made extrusion die casting of aluminum profiles

Keyword:

Category:

Tel:

Phone:

Custom-made extrusion die casting of aluminum profiles

Extruded aluminum profiles for enclosures have the following characteristics and applications:

Characteristics

Lightweight and high strength: Aluminum profiles are lightweight but have high strength and rigidity, meeting the load-bearing and protective needs of enclosures. Compared to steel, aluminum profiles are about 33% lighter while retaining sufficient strength.

Good thermal conductivity: Aluminum profiles have excellent thermal conductivity, enabling effective heat dissipation and making them suitable for equipment enclosures requiring thermal management.

Corrosion resistance: A natural oxide film forms on the surface of aluminum profiles, providing good corrosion resistance. This can be further enhanced through surface treatments such as anodizing.

Design flexibility: The extrusion process can produce complex cross-sectional shapes and sizes, allowing for customized enclosure shapes and structures to meet specific needs.

Good machinability: Aluminum profiles are easy to cut, punch, weld, bend, and undergo other secondary processing, adapting to various complex enclosure designs.

High cost-effectiveness: The extrusion process is simple, with low mold costs and short processing cycles, making it suitable for mass production.

Environmental friendliness: Aluminum profiles are recyclable materials that meet environmental requirements.

Applications

Electronic equipment enclosures: Widely used to house electronic components such as circuit boards, power supplies, and control panels, providing dust, moisture, and electromagnetic interference protection. Examples include CPU and GPU heatsinks, electronic device housings, and LED panel frames.

Instrument and meter enclosures: Used to protect sensitive equipment such as sensors, instruments, and measuring tools, providing a safe and stable measurement environment.

Industrial control enclosures: Used to install control panels and switches, capable of withstanding harsh environments with extreme temperatures, humidity, and vibration.

Communication equipment enclosures: Used for routers, modems, and wireless devices, preventing electromagnetic interference and ensuring reliable communication.

Automotive electronic enclosures: Used for housings of automotive electronic control units (ECUs), sensors, and connectors, capable of withstanding vibration, temperature fluctuations, and humid environments.

Medical equipment enclosures: Used for patient monitors, diagnostic equipment, and laboratory equipment, providing a clean and sterile protective environment.

LED lighting enclosures: Used to house LED modules and drivers, providing thermal management, dust and moisture protection, and ease of installation.

Extruded aluminum profiles for enclosures are widely used in electronics, industrial, automotive, medical, and lighting fields due to their lightweight, high-strength, good thermal conductivity, and corrosion resistance.

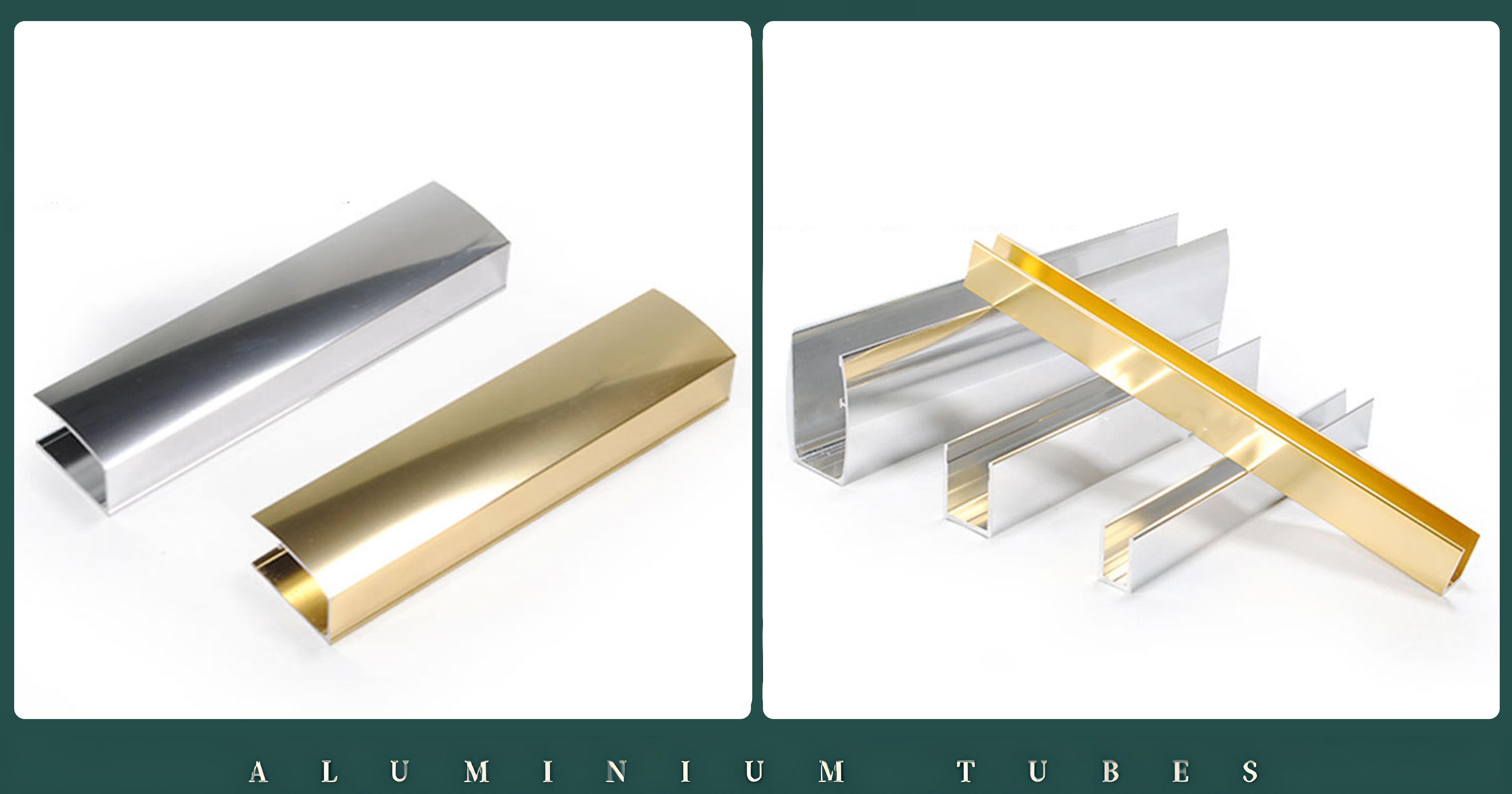

Chengyi Aluminum Industry (Shandong) Co., Ltd. is headquartered in Tianjin and has branch offices in Shandong and Jiangsu. The company mainly produces various high-quality aluminum profiles, aluminum tubes, square aluminum tubes, aluminum rods, aluminum strips, and conveyor line aluminum materials. The main grades include 1060, 1100, 3003, 5052, 5083, 6061, 6063, 6082, 6463, 6005, 6005A, 6060, 7075, etc. We have a large stock of various products available and offer fast delivery.

The company has integrated production from design to mold making, extrusion, processing, and surface treatment, with 19 extrusion presses ranging from 600 to 7500 tons. We also have modern welding technology and advanced surface treatment technology, including hard anodizing, anodizing coloring, three-acid bright silver, sandblasting anodizing, acid sandblasting anodizing, alkali sandblasting anodizing, powder coating, and wire drawing. Responding to the transformation of old and new kinetic energy, we are customer-oriented, professionally designing and processing to achieve a better combination of mechanics and aesthetics.

Chengyi people adhere to the corporate culture of "humility, responsibility, innovation, and integrity," upholding our duties, integrating knowledge and action, and striving to make better aluminum alloy products!

Prev

Prev

Related Products